PDC drill bits vs Tricone bits vs DTH drill bits

When encountering hard rocks during drilling, choosing the right drill bit is essential for maximizing efficiency, minimizing costs, and ensuring long tool life. This article focuses on three key aspects of drill bits: what PDC drill bits are, how they work, and their benefits. Additionally, we’ll compare PDC drill bits with tricone and DTH (down-the-hole) bits to help you make an informed decision.

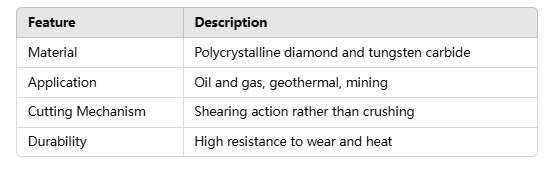

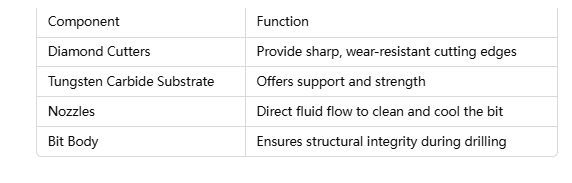

What Are PDC Drill Bits?

PDC (Polycrystalline Diamond Compact) drill bits are advanced drilling tools designed for hard rock formations. They are constructed by fusing synthetic diamond particles with a tungsten carbide substrate, creating a super-hard cutting surface that excels in extreme conditions.

How Do PDC Drill Bits Work?

PDC drill bits function through a shearing mechanism. Unlike traditional crushing methods, they use sharp diamond cutters to slice through rock. The bit rotates at high speeds, with hydraulic jets removing debris and cooling the bit during operation. This mechanism is highly efficient for hard and abrasive formations.

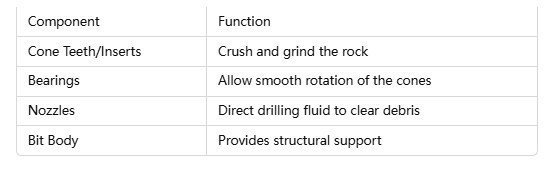

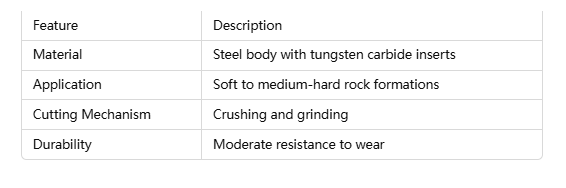

What Are Tricone Bits?

Tricone bits are versatile drilling tools designed with three rotating cones equipped with teeth or inserts. They are primarily used in soft to medium-hard rock formations and operate by crushing and grinding the rock surface as the cones rotate.

How Do Tricone Bits Work?

Tricone bits work by rotating three interlocked cones that crush and grind the rock as the bit moves downward. The teeth or inserts on the cones penetrate the rock surface, breaking it into smaller fragments. Drilling fluid is used to clear debris and cool the bit during operation.

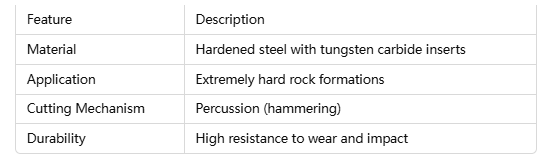

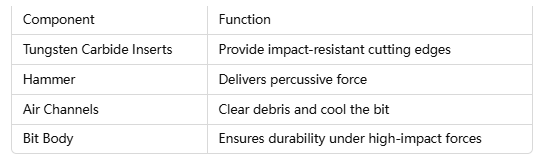

What Are DTH Bits?

Down-the-hole (DTH) bits are specialized drilling tools used for extremely hard rock formations. They operate through a percussive mechanism, where a hammer inside the drill string strikes the bit repeatedly to break the rock.

How Do DTH Bits Work?

DTH bits function by transferring percussive energy from a hammer located directly above the bit. The bit strikes the rock surface repeatedly, breaking it into fragments. This mechanism is highly effective for deep and hard rock drilling.

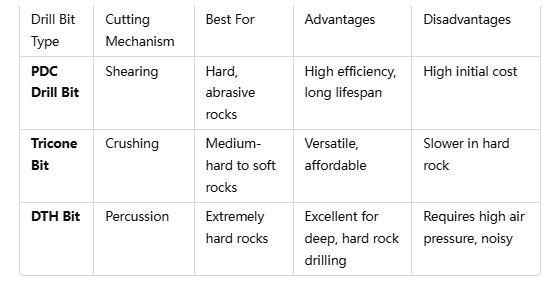

Comparing PDC, Tricone, and DTH Drill Bits

Selecting the right drill bit depends on factors like rock hardness, cost, and application. Below is a comparison of PDC, tricone, and DTH bits to guide your choice:

Conclusion

For hard rock drilling, PDC drill bits are an excellent choice due to their efficiency and durability. However, tricone and DTH bits also have their merits in specific conditions. Consider the type of rock formation, operational costs, and desired efficiency when selecting a drill bit. With the right tool, you can maximize performance and minimize downtime.

news-CBT Rock PDC Bit Manufacturer

news-CBT Rock PDC Bit Manufacturer