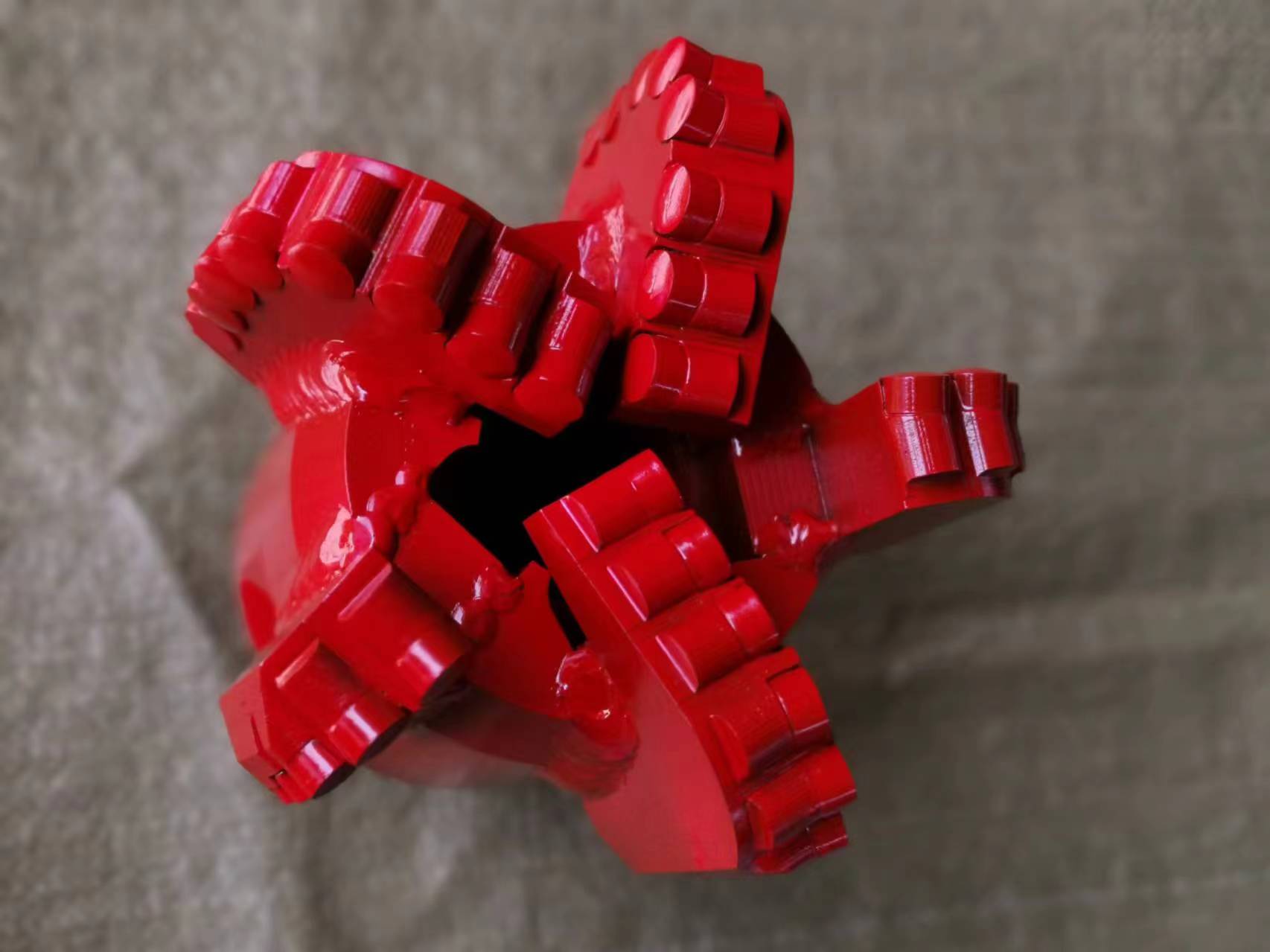

What is a PDC Drill Bit?

Definition and Characteristics

A PDC (Polycrystalline Diamond Compact) drill bit is a type of drilling tool widely used in the oil, gas, mining, and geothermal industries. It features synthetic diamond cutters fused on a tungsten carbide substrate. These cutters provide exceptional hardness, thermal stability, and wear resistance, allowing PDC bits to drill through hard and abrasive rock formations much faster than traditional roller cone bits.

Key characteristics of PDC drill bits include:

-

High drilling efficiency due to sharp diamond cutting edges.

-

Longer service life compared to steel-tooth or roller-cone bits.

-

No moving parts, which reduces mechanical failure risks.

-

Cost-effective over time, since fewer bit changes are required.

How Does a PDC Drill Bit Function?

PDC drill bits cut rock by a shearing action rather than crushing. The diamond cutters scrape and shear rock fragments away, which requires less energy than impact drilling. The drilling mud system then carries the cuttings out of the borehole.

-

The diamond layer provides hardness for cutting.

-

The tungsten carbide base offers toughness and impact resistance.

-

The bit body design (steel body or matrix body) helps manage hydraulic flow and durability.

This shearing mechanism makes PDC bits especially effective in sedimentary formations such as shale, limestone, and sandstone.

How to Drill with PDC Bits?

Using a PDC bit effectively requires proper drilling practices:

-

RPM (rotations per minute): Higher than roller cone bits to maximize shearing.

-

WOB (weight on bit): Controlled to avoid cutter damage.

-

Mud flow and hydraulics: Must be optimized to clean cuttings and cool the cutters.

-

Bit selection: Choose bit design based on formation hardness and abrasiveness.

Operators often use real-time monitoring systems to adjust drilling parameters and extend bit life.

FAQ – PDC Drill Bits

1. Are PDC bits better than roller cone bits?

PDC bits excel in soft to medium hard formations like shale, sandstone, or limestone because of the shearing action. They usually offer higher ROP (rate of penetration) and longer life. Roller cone bits may still be preferred in very hard, abrasive, or highly fractured formations.

2. What formations are PDC bits best for?

-

Soft to medium sedimentary rocks: shale, limestone, sandstone.

-

Certain hard formations if high-quality cutters and matrix body bits are used.

-

Avoid extremely abrasive or heavily fractured formations unless specifically designed bits are chosen.

3. How can I maximize the life of a PDC bit?

-

Maintain proper WOB and RPM based on formation type.

-

Ensure mud flow is sufficient to cool cutters and remove cuttings.

-

Monitor drilling conditions in real time.

-

Inspect and repair steel body bits when possible.

4. Can PDC bits drill directional wells?

Yes. PDC bits are commonly used in directional and horizontal drilling due to stable cutting performance and predictable steering response. Proper bit design and hydraulics are essential for accurate directional control.

5. How do I know when a PDC bit needs replacement?

-

Sharp drop in ROP.

-

Excessive vibration or torque fluctuations.

-

Visible cutter wear, chipping, or bit body erosion.

-

Unusual mud cuttings or stuck pipe incidents.

6. Are all PDC bits compatible with my drilling rig?

-

Check the bit connection type (API, NC, or other).

-

Ensure diameter and load capacity match rig capabilities.

-

Confirm hydraulic and RPM requirements can be met by your rig.

7. Can PDC bits be repaired?

-

Steel body bits: can replace damaged cutters and extend life.

-

Matrix body bits: limited repair options; usually replaced after wear.

8. How do I choose the right PDC bit for my operation?

-

Match the formation type and hardness.

-

Consider bit diameter, cutter size, density, and arrangement.

-

Review past drilling performance data from similar wells.

-

Consult with the bit manufacturer for optimized design.

9. What is the typical cost per drilling foot with a PDC bit?

-

Depends on formation, bit life, and ROP.

-

PDC bits often reduce bit changes and downtime, making the overall drilling cost per foot lower than roller cone bits, despite higher upfront cost.

news-CBT Rock PDC Bit Manufacturer

news-CBT Rock PDC Bit Manufacturer